Nante Industrial Plug Supports High Impact Operations at Quay Cranes

In the fast evolving realm of port operations an Industrial Plug delivers the robust connectivity required to power heavy duty equipment with minimal downtime. As terminals embrace automated container movers and remote controlled quay cranes the need for a reliable power interface becomes essential. Engineered for heavy wear and high impact conditions these rugged connectors ensure uninterrupted energy transfer even amid the dust spray and mechanical stress of bulk cargo handling.

Portside cranes and electric rail vehicles demand components that withstand constant motion and harsh elements. Industrial Plugs designed with reinforced housings and abrasion resistant insulating materials excel under repetitive coupling and uncoupling cycles. Their precision machined contacts maintain optimal conductivity while preventing arcing when cables engage or disengage from power outlets. This secure mating action safeguards sensitive onboard electronics and prevents costly disruptions during critical loading sequences.

Multi pole transmission capability distinguishes specialized plugs used in container terminals. By accommodating several circuits within a single sleeve these compact connectors reduce cable clutter and streamline deck layouts. Operators benefit from clear channel separation that prevents phase mix ups, while maintenance crews appreciate the color coded shells that speed identification. With sealed gaskets and IP rated barriers these multi pole units also keep moisture and foreign particles at bay, preserving electrical integrity on exposed quay structures.

Wear and impact resilience are critical in port environments where heavy machinery frequently grazes connection points. Industrial Plugs with reinforced rubberized bumpers and metal overmolds absorb shocks and prevent damage from accidental knocks. The result is extended service life and fewer replacement cycles. Such durability aligns with lifecycle cost objectives, allowing facility managers to focus capital on modernization projects rather than on frequent hardware swaps.

Ergonomic design features support swift coupling operations on deck and in workshops. Large grip surfaces and intuitive locking rings enable dockworkers to engage connectors securely, even while wearing thick gloves. Quick release mechanisms eject cables safely under load off conditions, avoiding strain on both connector and operator. These human centred details improve workflow speed and reduce the risk of repetitive strain incidents during long shift handling tasks.

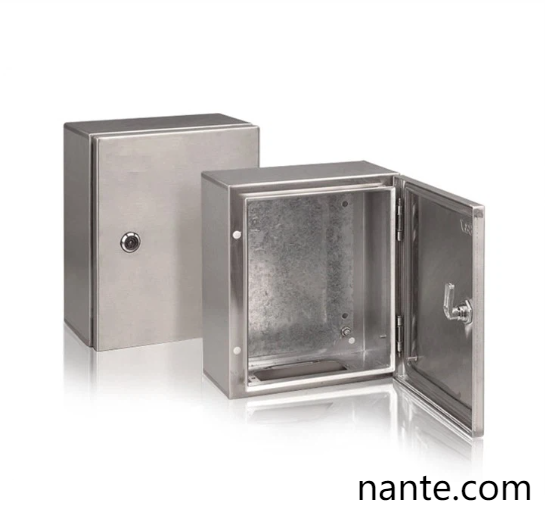

Customization options further adapt plugs to unique terminal requirements. High temperature variants resist radiant heat from nearby engines and exhaust stacks. Marine grade finishes protect against salt laden air, making stainless steel shells ideal for vessels and dockside cranes. Specialty inserts accommodate signal lines and ground wires within the same connector body, enabling integrated power and communication channels for remote diagnostics and control feedback loops.

Safety remains the foremost concern in any electrified handling operation. Industrial Plugs incorporate built in interlocks that prevent live contacts from exposure until fully engaged. Visible indicators confirm correct seating, while captive safety latches lock connectors into position during active loads. In the event of an unexpected tug away the internal mechanisms isolate live circuits instantly, averting arc faults and protecting both personnel and machinery.

Maintenance protocols are simplified through modular designs that allow field replacement of individual segments. Technicians can swap out worn contacts or gaskets without dismantling entire assemblies, reducing downtime and labor hours. Routine inspections become straightforward courtesy of transparent covers and service friendly access points. This modularity supports predictive upkeep strategies, ensuring critical load bearing equipment remains online when workflow demands peak.

Integration with smart monitoring platforms enhances visibility across sprawling terminal complexes. By equipping plugs with embedded sensor modules operators can collect real time data on current draw and connection health. Dashboards alert maintenance teams to signs of overheating or wear before failures occur. This proactive stance aligns with broader digital transformation initiatives aimed at maximizing uptime and optimizing asset utilization across maritime supply chains.

Selecting the right power interface technology empowers port operators to meet the challenges of automated cargo handling and electrified vehicle fleets. Solutions that combine impact resistance multi circuit transmission and ergonomic coupling features create a dependable backbone for next generation terminals. Discover how our advanced connector series can elevate your facility's efficiency and safety at www.nante.com .

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness