How Do Omani Stretch Film Manufacturers Ensure Product Consistency?

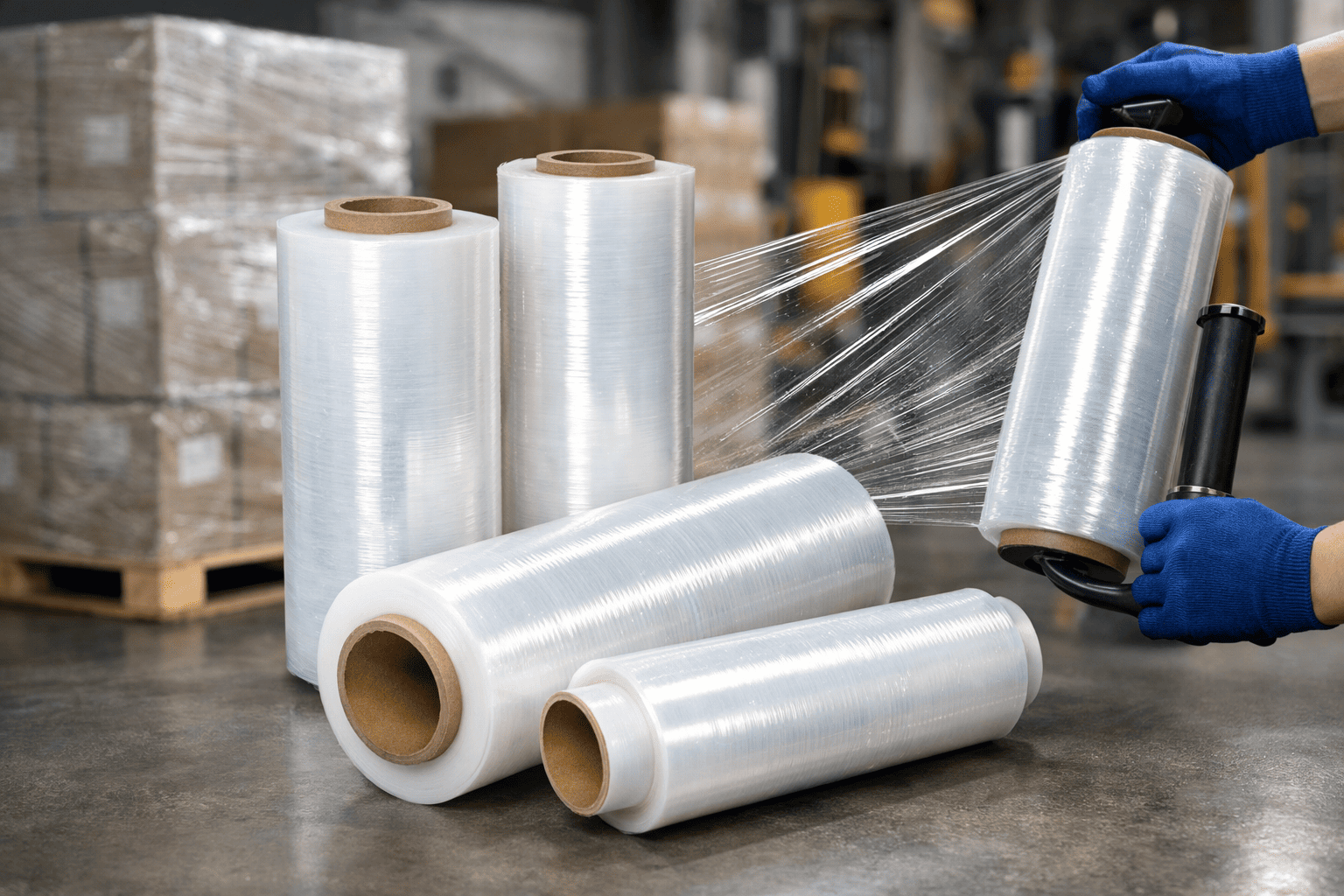

In today’s fast-moving logistics and packaging landscape, consistency isn’t a luxury—it’s a necessity. For businesses across Oman that rely on secure, durable packaging, the role of stretch film manufacturers in oman is more critical than ever. Whether it’s safeguarding goods during long-distance transport or maintaining load stability in warehouses, consistent stretch film quality directly impacts operational efficiency and customer trust.

So, how do Omani manufacturers consistently deliver high-quality stretch films despite fluctuating raw material prices, demanding industry standards, and diverse customer needs? Let’s break it down.

Why Product Consistency Matters in Stretch Film Manufacturing

Stretch film may look simple, but its performance depends on precise factors like thickness uniformity, tensile strength, elasticity, and cling. Even minor inconsistencies can lead to pallet failures, damaged goods, or increased material usage.

According to packaging industry insights, businesses can reduce packaging waste by up to 15–20% when using consistently manufactured stretch film. This makes consistency not just a quality issue but also a cost and sustainability concern—both top priorities in Oman’s growing industrial sector.

Advanced Raw Material Selection and Testing

One of the first steps stretch film manufacturers in Oman take to ensure consistency is sourcing high-grade raw materials, typically linear low-density polyethylene (LLDPE). Reliable suppliers and long-term procurement contracts help stabilize material quality.

Before production even begins, raw materials undergo:

-

Melt flow index (MFI) testing

-

Density and clarity checks

-

Contamination screening

As one production manager at an Omani packaging facility put it, “You can’t make a consistent product from inconsistent inputs. Quality starts at the granule level.”

State-of-the-Art Extrusion Technology

Modern Omani manufacturers invest heavily in cast and blown film extrusion lines equipped with automated controls. These systems monitor:

-

Temperature variations

-

Film gauge (thickness)

-

Cooling rates

-

Stretch and cling properties

Automated feedback loops allow real-time adjustments, minimizing human error and ensuring every roll meets the same performance benchmarks. This technology-driven approach has positioned Oman as a competitive packaging hub in the GCC region.

Strict Quality Control at Every Stage

Consistency doesn’t rely on one final inspection—it’s built into every stage of production. Leading stretch film manufacturers in Oman implement multi-level quality checks, including:

-

In-line thickness monitoring during extrusion

-

Lab testing for puncture resistance and load retention

-

Random batch sampling before dispatch

Many manufacturers follow ISO 9001 quality management systems, ensuring documented procedures, traceability, and continuous improvement.

Skilled Workforce and Continuous Training

Technology alone isn’t enough. Experienced technicians and engineers play a vital role in maintaining consistency. Omani manufacturers regularly train their teams on:

-

Equipment calibration

-

Process optimization

-

New material formulations

This blend of local expertise and international best practices ensures production standards remain stable even as demand scales up.

Standardized Processes and Customization Balance

While many customers require customized stretch film specifications—such as pre-stretched film or UV-resistant variants—manufacturers maintain strict internal standards. Core parameters like tensile strength ranges and elongation percentages are standardized, even in custom orders.

This balance allows flexibility without sacrificing reliability, a key reason why stretch film manufacturers in Oman are trusted by industries ranging from food and beverage to construction and pharmaceuticals.

Data-Driven Continuous Improvement

Consistency is not static—it’s refined over time. Manufacturers track production data, customer feedback, and defect rates to identify trends and improvement areas. Even a 1–2% variation reduction in film thickness can translate into significant material savings over large volumes.

Many facilities also benchmark against regional and international competitors, keeping Omani-made stretch film aligned with global expectations.

Conclusion: Consistency as a Competitive Advantage

For businesses operating in Oman, partnering with reliable stretch film manufacturers means fewer disruptions, lower costs, and stronger supply chain confidence. Through advanced technology, rigorous quality control, skilled teams, and data-driven processes, stretch film manufacturers in Oman have made product consistency a defining strength—not an afterthought.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness