-

Новости

- ИССЛЕДОВАТЬ

-

Страницы

-

Группы

-

Мероприятия

-

Статьи пользователей

-

Marketplace

-

Форумы

FDM Composite Large-Size Tooling Market Expands with Aerospace and Automotive Lightweighting Demand

"Key Drivers Impacting Executive Summary FDM Composite Large-Size Tooling Market Size and Share

CAGR Value

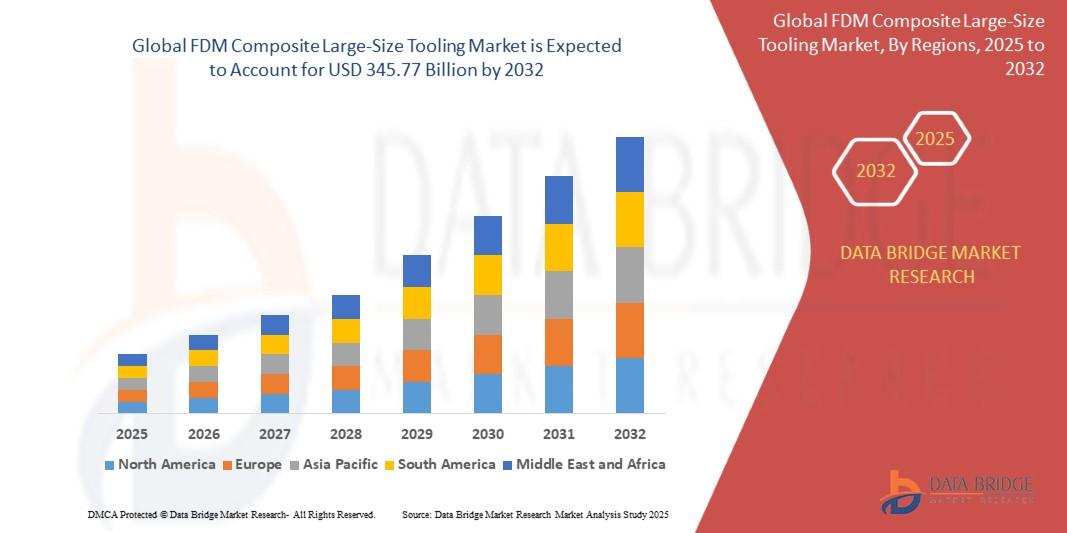

The global FDM composite large-size tooling market is expected to reach USD 457.79 million by 2032 from USD 345.77 million in 2025, growing with a substantial CAGR of 3.57% in the forecast period of 2025 to 2032.

A few of the most important objectives of the FDM Composite Large-Size Tooling report include studying and forecasting the market size in the worldwide market. Additionally, it defines, explains, and forecasts the market by various segments such as type, application, end-use, and region. The report also studies and compares the market status and forecast between major regions, namely, US, Europe, China, Japan, India, Southeast Asia, and the rest of the world. Moreover, the report analyzes the market's key players via SWOT analysis, value, and worldwide market share for leading players. This FDM Composite Large-Size Tooling Market research report gives answers to many of the critical business questions and challenges and proves to be a go-to solution.

FDM Composite Large-Size Tooling Market research report contains historic data, present market trends, the environment, technological innovation, upcoming technologies, and the technical progress in the related industry. Key data and information used while preparing this report has been collected from the consistent sources that range from journals, websites, research papers, case studies, and magazines. The research studies involved in this market report help to estimate several important aspects that include but are not limited to investment in a rising market, success of a new product, and expansion of market share. FDM Composite Large-Size Tooling Market research report works as a backbone for the growth of FDM Composite Large-Size Tooling Market

Understand market developments, risks, and growth potential in our FDM Composite Large-Size Tooling Market study. Get the full report:

https://www.databridgemarketresearch.com/reports/global-fdm-composite-large-size-tooling-market

FDM Composite Large-Size Tooling Industry Trends

Segments

- Material Type: Based on material type, the FDM composite large-size tooling market can be segmented into thermoset composites and thermoplastic composites. Thermoset composites are widely used in tooling applications due to their high strength and resistance to heat, making them ideal for manufacturing large-size parts. On the other hand, thermoplastic composites offer advantages such as ease of recycling and faster production cycles.

- Application: The market can also be segmented based on application into aerospace, automotive, wind energy, marine, and others. The aerospace sector is a significant consumer of FDM composite large-size tooling due to the need for lightweight yet durable components. The automotive industry is rapidly adopting FDM tooling for prototyping and manufacturing of complex parts.

- End-Use Industry: FDM composite large-size tooling finds applications across various end-use industries such as manufacturing, defense, energy, and others. The manufacturing sector dominates the market as manufacturers seek cost-effective and efficient tooling solutions to streamline their production processes.

Market Players

- Stratasys Ltd.: Stratasys is a key player in the FDM composite large-size tooling market, offering a range of advanced FDM printers and materials that cater to the aerospace and automotive industries. The company's innovative solutions have helped customers reduce lead times and enhance product quality.

- 3D Systems, Inc.: 3D Systems is another prominent player known for its cutting-edge 3D printing technologies that enable the production of high-quality composite tooling. The company's expertise in additive manufacturing has positioned it as a trusted partner for tooling applications in various industries.

- Hexcel Corporation: Hexcel specializes in advanced composites used in tooling applications for aerospace and defense sectors. The company's focus on lightweight yet durable materials has made it a preferred choice for large-size tooling solutions.

- General Electric Company: GE has made significant advancements in additive manufacturing technologies for large-size tooling, particularly in the aerospace industry. The company's investment in research and development has led to the development of innovative FDM composite tooling solutions.

- Thermwood Corporation: Thermwood offers a range of large-format 3D printers that are used for producing composite tooling for marine and wind energy applications. The company's technology enables the manufacturing of complex tooling geometries with high precision.

The global FDM composite large-size tooling market is poised for significant growth driven by increasing demand for lightweight and cost-effective tooling solutions across various industries. Companies investing in research and development to enhance material properties and 3D printing technologies are likely to gain a competitive edge in the market.

The FDM composite large-size tooling market is experiencing steady growth fueled by the increasing demand for advanced and efficient tooling solutions across various industries. One of the key drivers of this market is the shift towards lightweight materials with high strength characteristics, particularly in sectors such as aerospace and automotive. Manufacturers are increasingly turning to FDM composite large-size tooling to produce complex parts with improved performance and reliability. Additionally, the adoption of additive manufacturing technologies like 3D printing is revolutionizing the tooling industry by enabling faster production cycles and customization options.

In terms of material types, the market segmentation between thermoset composites and thermoplastic composites offers distinct advantages for different applications. While thermoset composites are known for their high strength and heat resistance, making them suitable for manufacturing large-size parts, thermoplastic composites provide benefits such as ease of recycling and shorter production cycles. This segmentation allows companies to choose the material that best suits their specific requirements and production processes, enhancing overall efficiency and cost-effectiveness.

When considering the applications of FDM composite large-size tooling, industries such as aerospace, automotive, wind energy, and marine stand out as major consumers of these advanced tooling solutions. The aerospace sector, in particular, relies heavily on FDM tooling for its lightweight yet durable components, enabling aircraft manufacturers to meet stringent performance standards while reducing overall weight. Similarly, the automotive industry is leveraging FDM composite tooling for prototyping and manufacturing complex parts, driving innovation and efficiency in the production process.

Furthermore, the end-use industry segmentation reveals the widespread applications of FDM composite large-size tooling across various sectors such as manufacturing, defense, and energy. The manufacturing sector, in particular, leads the market as companies seek cost-effective and efficient tooling solutions to streamline their production processes and gain a competitive edge in the market. With advancements in material properties and additive manufacturing technologies, companies are investing in research and development to enhance their FDM composite tooling offerings, positioning themselves as leaders in the evolving tooling market landscape.

In conclusion, the global FDM composite large-size tooling market is poised for significant growth as industries continue to prioritize lightweight, durable, and cost-effective tooling solutions. Market players such as Stratasys Ltd., 3D Systems, Inc., Hexcel Corporation, General Electric Company, and Thermwood Corporation are at the forefront of innovation in this space, offering advanced technologies and materials to meet the evolving needs of various industries. As companies focus on enhancing material properties, production processes, and customization options, the FDM composite large-size tooling market is expected to see continued expansion and innovation in the coming years.The FDM composite large-size tooling market is witnessing significant growth propelled by the rising demand for advanced and efficient tooling solutions in various industries. A key driver of this market evolution is the transition towards lightweight materials with high strength attributes, particularly in sectors like aerospace and automotive. Manufacturers are increasingly turning to FDM composite large-size tooling to produce intricate parts with enhanced performance and reliability. The adoption of additive manufacturing technologies, such as 3D printing, is revolutionizing the tooling industry by enabling quicker production cycles and customization options, further driving market growth and innovation.

The segmentation of the market based on material types, specifically thermoset composites and thermoplastic composites, offers distinct advantages tailored for different applications. Thermoset composites are renowned for their robustness and heat resistance, making them ideal for manufacturing large parts, whereas thermoplastic composites provide benefits like easy recyclability and shorter production cycles. This segmentation empowers companies to select materials that align with their specific requirements and production processes, thereby enhancing overall operational efficiency and cost-effectiveness.

In terms of applications, industries such as aerospace, automotive, wind energy, and marine emerge as prominent consumers of FDM composite large-size tooling. The aerospace sector heavily relies on FDM tooling for its lightweight yet sturdy components, enabling aircraft manufacturers to meet stringent performance standards while reducing overall weight. Similarly, the automotive industry leverages FDM composite tooling for prototyping and manufacturing complex parts, fostering innovation and efficiency in production processes.

Furthermore, the end-use industry segmentation underscores the extensive utilization of FDM composite large-size tooling across various sectors like manufacturing, defense, and energy. The manufacturing sector takes the lead in the market as companies seek economical and effective tooling solutions to streamline production processes and gain a competitive edge. With continuous advancements in material properties and additive manufacturing technologies, enterprises are investing in research and development to enhance their FDM composite tooling offerings, positioning themselves as frontrunners in the ever-evolving tooling market landscape.

To conclude, the global FDM composite large-size tooling market is poised for substantial growth as industries prioritize lightweight, durable, and cost-effective tooling solutions. Leading market players like Stratasys Ltd., 3D Systems, Inc., Hexcel Corporation, General Electric Company, and Thermwood Corporation are spearheading innovation, offering cutting-edge technologies and materials to meet the dynamic requirements of diverse industries. As companies focus on improving material characteristics, production processes, and customization options, the FDM composite large-size tooling market is projected to witness continuous expansion and innovation in the upcoming years, catering to the evolving needs of modern manufacturing and production environments on a global scale.

Break down the firm’s market footprint

https://www.databridgemarketresearch.com/reports/global-fdm-composite-large-size-tooling-market/companies

Nucleus is Data Bridge Market Research’s cutting-edge, cloud-based market intelligence platform that empowers organizations to make faster, smarter, data-driven decisions. Designed for strategic thinkers, researchers, and innovators, Nucleus transforms complex macroeconomic indicators, industry-specific trends, and competitive data into actionable insights through dynamic dashboards and real-time analytics. With capabilities spanning market access intelligence, competitive benchmarking, epidemiological analytics, global trade insights, and cross-sector strategy modeling, the platform unifies diverse datasets to help businesses identify opportunities, assess risks, and drive growth across regions and industries. Built on a powerful neural analytics engine, Nucleus bridges the gap between raw data and strategic execution, enabling users to visualize emerging trends, benchmark performance, and make informed decisions with confidence.

Get More Detail: https://www.databridgemarketresearch.com/nucleus/global-fdm-composite-large-size-tooling-market

FDM Composite Large-Size Tooling Market Reporting Toolkit: Custom Question Bunches

- What is the total valuation of the FDM Composite Large-Size Tooling industry this year?

- What will be the future growth outlook of the FDM Composite Large-Size Tooling Market?

- What are the foundational segments discussed in the FDM Composite Large-Size Tooling Market report?

- Who are the dominant players in FDM Composite Large-Size Tooling Market each region?

- What countries are highlighted in terms of revenue growth for FDM Composite Large-Size Tooling Market?

- What company profiles are included in the FDM Composite Large-Size Tooling Market report?

Browse More Reports:

Global Electronic Design Automation (EDA) Tools Market

Global Electronic Support Market

Global Embolic Protection Devices Market

Global Employee Referral Software Market

Global Emulsifiers in Animal Feed Application Market

Global Endoscopy Fluid Management Market

Global Engineering Services Outsourcing Market

Global Engine Oil Packaging Market

Global Eosinophilia Treatment Market

Global Epitope Tags Market

Global Epstein-Barr Virus Drug Market

Global E-Tailing Solutions Market

Global E-Transit Metro Ethernet Services Market

Global EV Charging Panelboard Market

Global Excoriation (Skin-picking) Disorder Market

About Data Bridge Market Research:

An absolute way to forecast what the future holds is to comprehend the trend today!

Data Bridge Market Research set forth itself as an unconventional and neoteric market research and consulting firm with an unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process. Data Bridge is an aftermath of sheer wisdom and experience which was formulated and framed in the year 2015 in Pune.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email:- corporatesales@databridgemarketresearch.com

"

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Игры

- Gardening

- Health

- Главная

- Literature

- Music

- Networking

- Другое

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness