Vinyl Acetate Monomer (VAM) Price Trend Report: Historical Prices, Quarterly Index Movements, Raw Material Cost Linkages, and Forward Price Expectations

Vinyl Acetate Monomer, often called VAM, is a chemical that quietly supports many everyday products. It is used to make paints, adhesives, coatings, textiles, packaging materials, and even some construction products. Because it is so widely used, changes in the Vinyl Acetate Monomer price trend often reflect broader movements in the chemical and manufacturing industries. Looking at this price trend in a simple and experience-based way helps businesses and buyers understand what is really driving the market.

Please Submit Your Query for Vinyl Acetate Monomer Price Trend, demand-supply, suppliers, market analysis:https://www.price-watch.ai/book-a-demo/

What Vinyl Acetate Monomer Is Used For

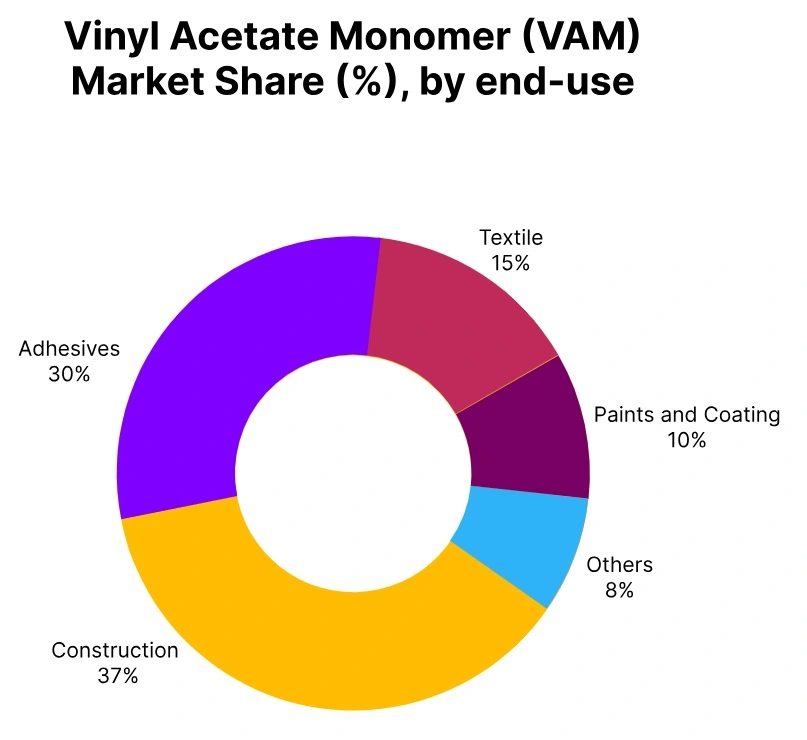

Vinyl Acetate Monomer is mainly used as a raw material to produce polymers and resins. These polymers later become paints for homes, adhesives for packaging, and coatings that protect surfaces. When construction activity increases or packaging demand grows, VAM consumption usually rises. On the other hand, when industrial activity slows, demand for Vinyl Acetate Monomer may soften. This close link between daily-use products and VAM demand plays an important role in shaping its price trend.

Raw Material Costs and Their Influence on Prices

One of the strongest factors affecting the Vinyl Acetate Monomer price trend is the cost of its raw materials. VAM is produced using ethylene and acetic acid, both of which are derived from petrochemical sources. When crude oil or natural gas prices rise, the cost of producing these inputs also increases. Manufacturers then face higher production expenses, which often leads to higher VAM prices in the market. When energy prices fall or raw material supply improves, Vinyl Acetate Monomer prices tend to stabilize or move downward.

Demand from Construction and Packaging Industries

The construction and packaging sectors are major consumers of Vinyl Acetate Monomer-based products. When construction activity is strong, there is more demand for paints, sealants, and adhesives. This increased usage pushes up the demand for VAM, supporting higher prices. Similarly, growth in e-commerce and food packaging increases the need for adhesives, which again lifts Vinyl Acetate Monomer demand. In periods when construction projects slow or packaging demand weakens, the Vinyl Acetate Monomer price trend often shows softer movement.

Impact of Supply Chain and Production Conditions

Supply conditions also play a big role in determining the Vinyl Acetate Monomer price trend. Planned maintenance shutdowns, unplanned plant outages, or production issues can reduce supply in the market. When supply becomes tight while demand remains steady, prices usually rise. On the other hand, when production capacity is high and inventories are well-stocked, suppliers may reduce prices to stay competitive. Transportation costs and logistics challenges can further influence prices, especially during times of global shipping disruptions.

Environmental Regulations and Sustainability Factors

Environmental rules and sustainability goals are becoming more important in the chemical industry. Stricter regulations can increase production costs for Vinyl Acetate Monomer manufacturers, especially if investments are needed for cleaner technologies. These additional costs may be reflected in the final price of VAM. At the same time, demand for eco-friendly adhesives and coatings can support steady consumption, helping maintain stable price levels over the long term.

Please Submit Your Query for Vinyl Acetate Monomer Price Trend, demand-supply, suppliers, market analysis:https://www.price-watch.ai/book-a-demo/

𝐀𝐛𝐨𝐮𝐭 𝐏𝐫𝐢𝐜𝐞-𝐖𝐚𝐭𝐜𝐡 𝐀𝐈

Price-Watch AI is an independent raw material price reporting agency that provides real-time price forecasts and data-driven insights into global raw material markets. Price-Watch AI specializes in tracking raw material prices, analyzing market trends, and delivering timely updates on plant shutdowns, supply disruptions, capacity expansions, and demand-supply dynamics. The Price-Watch AI platform empowers manufacturers, traders, and procurement professionals to make faster, smarter decisions. Leveraging AI-powered forecasting and over a decade of historical data, Price-Watch AI transforms market volatility into actionable opportunity.

Futura Tech Park,

C Block, 8th floor 334,

Old Mahabalipuram Road,

Sholinganallur, Chennai, Tamil Nadu, Pincode - 600119.

𝐋𝐢𝐧𝐤𝐞𝐝𝐈𝐧: https://www.linkedin.com/company/price-watch-ai/

𝐅𝐚𝐜𝐞𝐛𝐨𝐨𝐤: https://www.facebook.com/people/PriceWatch/61568490385598/

𝐓𝐰𝐢𝐭𝐭𝐞𝐫: https://x.com/pricewatchai

𝐖𝐞𝐛𝐬𝐢𝐭𝐞: https://www.price-watch.ai/

Vinyl Acetate Monomer, often called VAM, is a chemical that quietly supports many everyday products. It is used to make paints, adhesives, coatings, textiles, packaging materials, and even some construction products. Because it is so widely used, changes in the Vinyl Acetate Monomer price trend often reflect broader movements in the chemical and manufacturing industries. Looking at this price trend in a simple and experience-based way helps businesses and buyers understand what is really driving the market.

Please Submit Your Query for Vinyl Acetate Monomer Price Trend, demand-supply, suppliers, market analysis:https://www.price-watch.ai/book-a-demo/

What Vinyl Acetate Monomer Is Used For

Vinyl Acetate Monomer is mainly used as a raw material to produce polymers and resins. These polymers later become paints for homes, adhesives for packaging, and coatings that protect surfaces. When construction activity increases or packaging demand grows, VAM consumption usually rises. On the other hand, when industrial activity slows, demand for Vinyl Acetate Monomer may soften. This close link between daily-use products and VAM demand plays an important role in shaping its price trend.

Raw Material Costs and Their Influence on Prices

One of the strongest factors affecting the Vinyl Acetate Monomer price trend is the cost of its raw materials. VAM is produced using ethylene and acetic acid, both of which are derived from petrochemical sources. When crude oil or natural gas prices rise, the cost of producing these inputs also increases. Manufacturers then face higher production expenses, which often leads to higher VAM prices in the market. When energy prices fall or raw material supply improves, Vinyl Acetate Monomer prices tend to stabilize or move downward.

Demand from Construction and Packaging Industries

The construction and packaging sectors are major consumers of Vinyl Acetate Monomer-based products. When construction activity is strong, there is more demand for paints, sealants, and adhesives. This increased usage pushes up the demand for VAM, supporting higher prices. Similarly, growth in e-commerce and food packaging increases the need for adhesives, which again lifts Vinyl Acetate Monomer demand. In periods when construction projects slow or packaging demand weakens, the Vinyl Acetate Monomer price trend often shows softer movement.

Impact of Supply Chain and Production Conditions

Supply conditions also play a big role in determining the Vinyl Acetate Monomer price trend. Planned maintenance shutdowns, unplanned plant outages, or production issues can reduce supply in the market. When supply becomes tight while demand remains steady, prices usually rise. On the other hand, when production capacity is high and inventories are well-stocked, suppliers may reduce prices to stay competitive. Transportation costs and logistics challenges can further influence prices, especially during times of global shipping disruptions.

Environmental Regulations and Sustainability Factors

Environmental rules and sustainability goals are becoming more important in the chemical industry. Stricter regulations can increase production costs for Vinyl Acetate Monomer manufacturers, especially if investments are needed for cleaner technologies. These additional costs may be reflected in the final price of VAM. At the same time, demand for eco-friendly adhesives and coatings can support steady consumption, helping maintain stable price levels over the long term.

Please Submit Your Query for Vinyl Acetate Monomer Price Trend, demand-supply, suppliers, market analysis:https://www.price-watch.ai/book-a-demo/

𝐀𝐛𝐨𝐮𝐭 𝐏𝐫𝐢𝐜𝐞-𝐖𝐚𝐭𝐜𝐡 𝐀𝐈

Price-Watch AI is an independent raw material price reporting agency that provides real-time price forecasts and data-driven insights into global raw material markets. Price-Watch AI specializes in tracking raw material prices, analyzing market trends, and delivering timely updates on plant shutdowns, supply disruptions, capacity expansions, and demand-supply dynamics. The Price-Watch AI platform empowers manufacturers, traders, and procurement professionals to make faster, smarter decisions. Leveraging AI-powered forecasting and over a decade of historical data, Price-Watch AI transforms market volatility into actionable opportunity.

Futura Tech Park,

C Block, 8th floor 334,

Old Mahabalipuram Road,

Sholinganallur, Chennai, Tamil Nadu, Pincode - 600119.

𝐋𝐢𝐧𝐤𝐞𝐝𝐈𝐧: https://www.linkedin.com/company/price-watch-ai/

𝐅𝐚𝐜𝐞𝐛𝐨𝐨𝐤: https://www.facebook.com/people/PriceWatch/61568490385598/

𝐓𝐰𝐢𝐭𝐭𝐞𝐫: https://x.com/pricewatchai

𝐖𝐞𝐛𝐬𝐢𝐭𝐞: https://www.price-watch.ai/

Vinyl Acetate Monomer (VAM) Price Trend Report: Historical Prices, Quarterly Index Movements, Raw Material Cost Linkages, and Forward Price Expectations

Vinyl Acetate Monomer, often called VAM, is a chemical that quietly supports many everyday products. It is used to make paints, adhesives, coatings, textiles, packaging materials, and even some construction products. Because it is so widely used, changes in the Vinyl Acetate Monomer price trend often reflect broader movements in the chemical and manufacturing industries. Looking at this price trend in a simple and experience-based way helps businesses and buyers understand what is really driving the market.

👉 👉 👉 Please Submit Your Query for Vinyl Acetate Monomer Price Trend, demand-supply, suppliers, market analysis:https://www.price-watch.ai/book-a-demo/

What Vinyl Acetate Monomer Is Used For

Vinyl Acetate Monomer is mainly used as a raw material to produce polymers and resins. These polymers later become paints for homes, adhesives for packaging, and coatings that protect surfaces. When construction activity increases or packaging demand grows, VAM consumption usually rises. On the other hand, when industrial activity slows, demand for Vinyl Acetate Monomer may soften. This close link between daily-use products and VAM demand plays an important role in shaping its price trend.

Raw Material Costs and Their Influence on Prices

One of the strongest factors affecting the Vinyl Acetate Monomer price trend is the cost of its raw materials. VAM is produced using ethylene and acetic acid, both of which are derived from petrochemical sources. When crude oil or natural gas prices rise, the cost of producing these inputs also increases. Manufacturers then face higher production expenses, which often leads to higher VAM prices in the market. When energy prices fall or raw material supply improves, Vinyl Acetate Monomer prices tend to stabilize or move downward.

Demand from Construction and Packaging Industries

The construction and packaging sectors are major consumers of Vinyl Acetate Monomer-based products. When construction activity is strong, there is more demand for paints, sealants, and adhesives. This increased usage pushes up the demand for VAM, supporting higher prices. Similarly, growth in e-commerce and food packaging increases the need for adhesives, which again lifts Vinyl Acetate Monomer demand. In periods when construction projects slow or packaging demand weakens, the Vinyl Acetate Monomer price trend often shows softer movement.

Impact of Supply Chain and Production Conditions

Supply conditions also play a big role in determining the Vinyl Acetate Monomer price trend. Planned maintenance shutdowns, unplanned plant outages, or production issues can reduce supply in the market. When supply becomes tight while demand remains steady, prices usually rise. On the other hand, when production capacity is high and inventories are well-stocked, suppliers may reduce prices to stay competitive. Transportation costs and logistics challenges can further influence prices, especially during times of global shipping disruptions.

Environmental Regulations and Sustainability Factors

Environmental rules and sustainability goals are becoming more important in the chemical industry. Stricter regulations can increase production costs for Vinyl Acetate Monomer manufacturers, especially if investments are needed for cleaner technologies. These additional costs may be reflected in the final price of VAM. At the same time, demand for eco-friendly adhesives and coatings can support steady consumption, helping maintain stable price levels over the long term.

👉 👉 👉 Please Submit Your Query for Vinyl Acetate Monomer Price Trend, demand-supply, suppliers, market analysis:https://www.price-watch.ai/book-a-demo/

𝐀𝐛𝐨𝐮𝐭 𝐏𝐫𝐢𝐜𝐞-𝐖𝐚𝐭𝐜𝐡 𝐀𝐈

Price-Watch AI is an independent raw material price reporting agency that provides real-time price forecasts and data-driven insights into global raw material markets. Price-Watch AI specializes in tracking raw material prices, analyzing market trends, and delivering timely updates on plant shutdowns, supply disruptions, capacity expansions, and demand-supply dynamics. The Price-Watch AI platform empowers manufacturers, traders, and procurement professionals to make faster, smarter decisions. Leveraging AI-powered forecasting and over a decade of historical data, Price-Watch AI transforms market volatility into actionable opportunity.

Futura Tech Park,

C Block, 8th floor 334,

Old Mahabalipuram Road,

Sholinganallur, Chennai, Tamil Nadu, Pincode - 600119.

𝐋𝐢𝐧𝐤𝐞𝐝𝐈𝐧: https://www.linkedin.com/company/price-watch-ai/

𝐅𝐚𝐜𝐞𝐛𝐨𝐨𝐤: https://www.facebook.com/people/PriceWatch/61568490385598/

𝐓𝐰𝐢𝐭𝐭𝐞𝐫: https://x.com/pricewatchai

𝐖𝐞𝐛𝐬𝐢𝐭𝐞: https://www.price-watch.ai/

0 Kommentare

0 Anteile

590 Ansichten

0 Vorschau